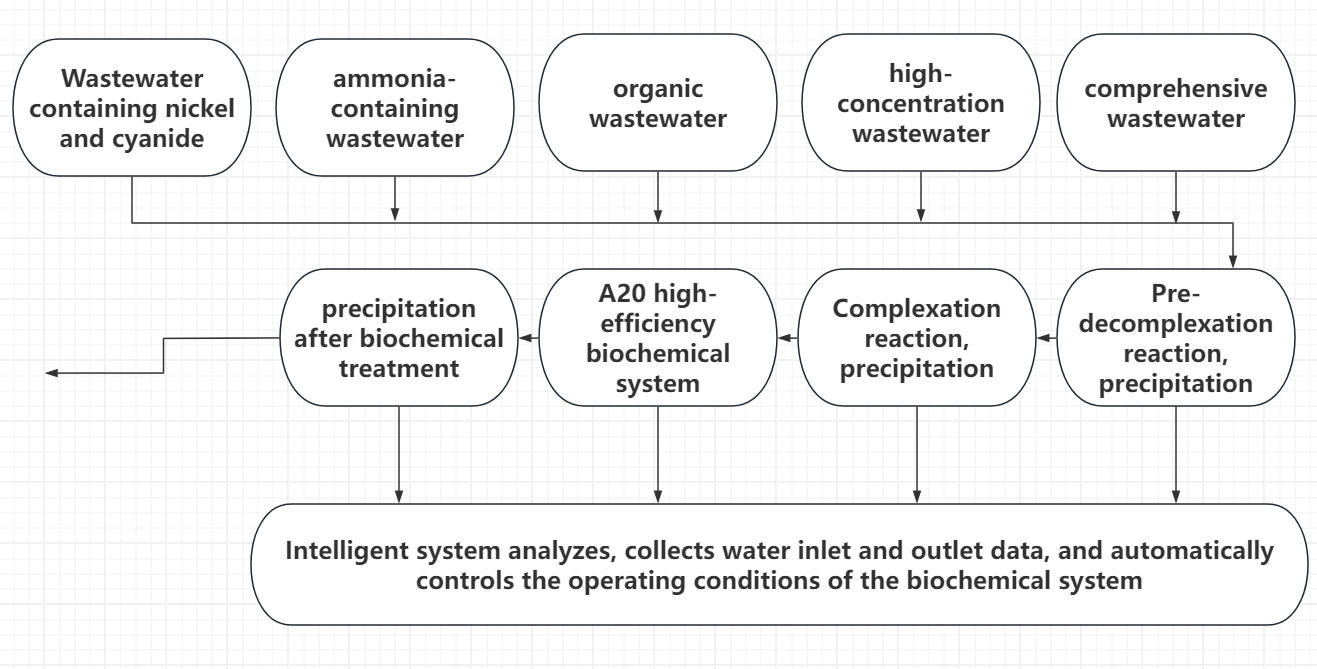

Process Introduction

Wastewater treatment flowchart

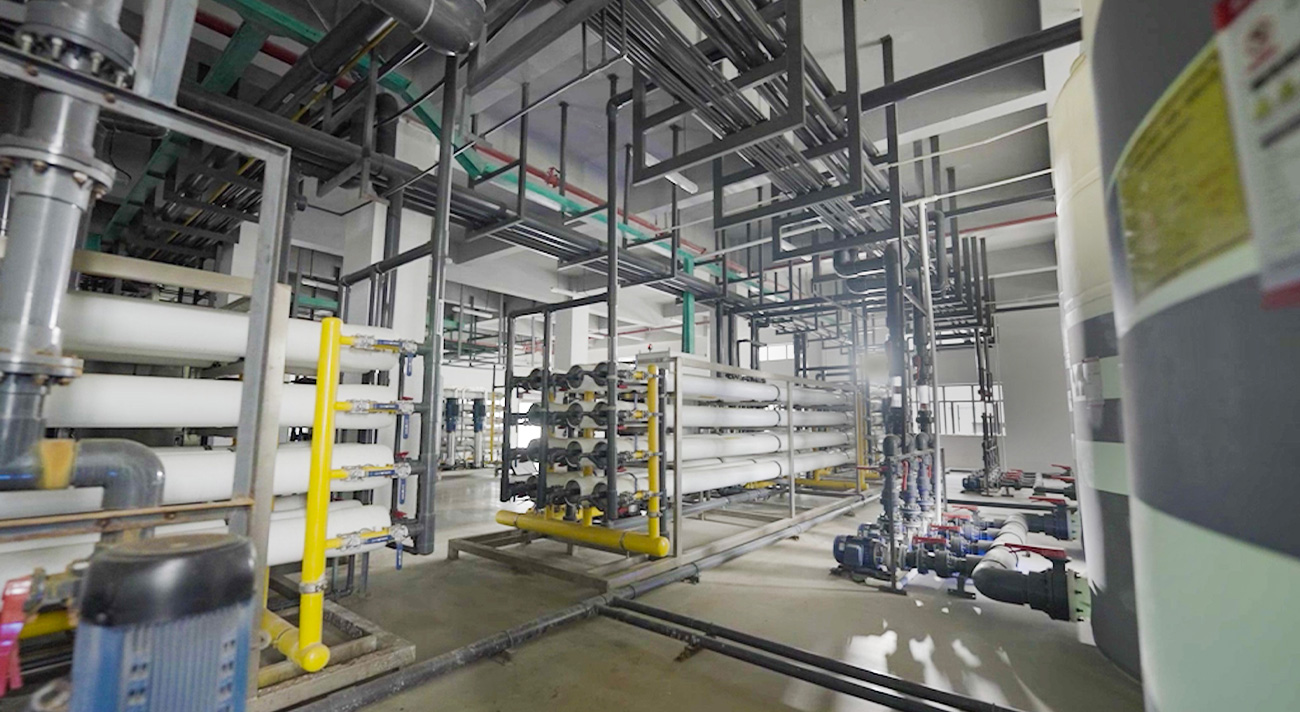

PCB pure water treatment system & PCB reclaimed water reuse system

PCB pure water treatment system:

Reverse osmosis pure water equipment technology is the most advanced and energy-efficient membrane separation technology available today. Its principle is to separate other substances from water based on their inability to pass through the permeable membrane under the influence of a pressure higher than the osmotic pressure of the solution. Due to the very small pore size of the reverse osmosis membrane (only about 10A), it can effectively remove dissolved salts, colloids, microorganisms, organic matter, etc. (with a removal rate of up to 97%-98%) from water. Reverse osmosis is currently the most widely used desalination technology in high-purity water equipment, and its separation targets are ions in the solution and organic matter with molecular weights in the hundreds: reverse osmosis (RO), ultrafiltration (UF), microfiltration (MF), and electrodialysis (EDI) technologies all belong to membrane separation technology. During the production process, there is no need to increase secondary investment in sewage environmental protection. Currently, the desalination rate of highly selective reverse osmosis membrane elements can reach up to 99.7%.

PCB water reuse system:

Reclaimed water mainly refers to non-potable water that can be reused within a certain range after urban sewage and factory wastewater are treated to meet certain water quality standards. Because its water quality is between that of traditional drinking water and wastewater, it is called reclaimed water.

Reclaimed water reuse technology is currently an important approach to conserve water resources and prevent water pollution. It is also a new environmental protection technology and process that China emphasizes on promoting. Reclaimed water reuse not only alleviates urban water supply pressure but also significantly saves enterprises' sewage discharge fees and reduces production costs, achieving good economic, environmental, and social benefits.

Advantages of PCB water reuse system:

1、75% of the wastewater from circuit board and electroplating factories is recycled;

2、The quality of the recycled water remains stable at 100us/cm;

3、The overall recovery rate of the electroplating integrated wastewater recycling system is over 60%. The wastewater is recycled through the wastewater recovery system, thus saving more than 60% of the wastewater discharge cost.

4、It has good economic benefits, and the initial design cost can be recovered within 1-2 years

5、The system boasts a long lifespan, low failure rate, and convenient maintenance

6、The discharged water can meet the latest environmental protection regulations' Grade I emission standards, reducing pollution to nearby water bodies and improving the human living environment.

Microfiltration membrane technology

The nanoscale carbon powder filtration system is primarily designed to filter nanoscale particulate carbon powder. The system comprises modules such as microfiltration circulation filtration, chemical cleaning, and control. With a high degree of automation, the system features automatic filtration and automatic cleaning, which extends the lifespan of the membrane fibers and ensures a filtration accuracy of 0.1um, effectively removing viruses and other particles. The application of the microfiltration membrane filtration system significantly improves various chemical indicators, with the turbidity of filtered water being around 0.012NTU. Additionally, the system is resistant to acids, alkalis, and strong oxidants, boasting a service life of over 5 years.

Efficient biochemical equipment

The microbial density, which is 20 times higher than that of traditional biochemical systems, will bring about unique effects in the later stages of wastewater treatment.

same industry technology

1、COD treatment cannot consistently meet the standards.

2、Currently, there is no integrated equipment on the market that can handle organic wastewater with high material consumption and membrane residue production, while maintaining a high workload.

Our Advantages

1、COD treatment is no longer a problem that troubles you.

2、Organic wastewater treatment does not require further floating selection, reducing material consumption and tedious slag removal work while also reducing membrane slag production.

3、It is possible to simultaneously biodegrade the membrane residue produced by the production line without causing COD to exceed the standard, and the organic matter has been cleared to zero.

4、The total bacterial count is 20 times higher than that of traditional contact oxidation or activated sludge treatment methods.