Introduction to Exhaust Gas Treatment Equipment

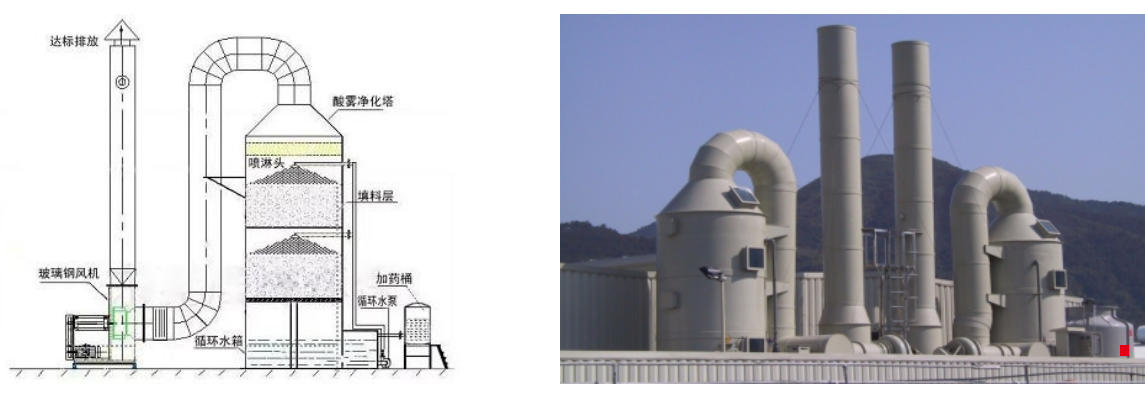

Acid alkali washing tower

Acid alkali scrubbing tower can be used for the treatment of acid alkali waste gas and dust/smoke generated in industrial production. It utilizes the principle of acid-base neutralization reaction to bring acidic (alkaline) waste gas into contact with alkaline (acidic) circulating aqueous solution, absorb acidic (alkaline) substances in the waste gas through washing solution, convert gaseous acidic and alkaline pollutants into salts, and discharge them into the sewage treatment system for treatment. The gas emissions after spray treatment reach the atmosphere. The acid-base washing tower has the advantages of simple structure, easy operation, high processing capacity, and low resistance, and is widely used in industries such as circuit boards, electroplating, chemical engineering, semiconductors, and pharmaceuticals.

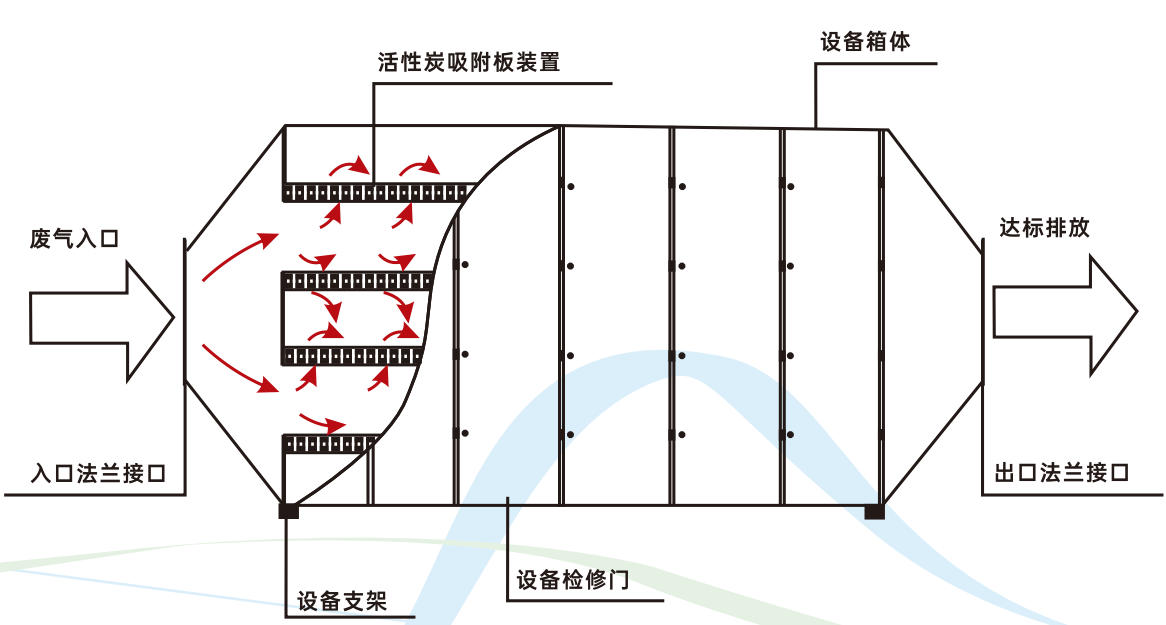

Activated carbon adsorption tower

Activated carbon adsorption tower can be used for organic waste gas treatment and odorous waste gas treatment. It utilizes the adsorption capacity of activated carbon adsorbent surface to make the exhaust gas come into contact with the porous activated carbon adsorbent on the large surface. The pollutants in the exhaust gas are adsorbed on the surface of the activated carbon, separated from the gas mixture, and the purified gas is discharged at high altitude. Mainly used in industries such as pharmaceuticals, metallurgy, chemical engineering, machinery, electronics, electrical appliances, painting, footwear, rubber, plastics, printing, etc.

Wet electrostatic smoke removal tower

Wet electrostatic smoke removal tower can be used for acid waste gas treatment and oil/smoke waste gas treatment. It uses a high-voltage electrostatic device to apply negative high-voltage electricity to the corona wire installed in the wet electrostatic smoke removal tower, thereby forming an uneven high-voltage electrostatic field between the corona wire and the precipitation electrode tube, and the two electrodes are arranged coaxially. The electric field strength at each point in the precipitation electrode tube is inversely proportional to the distance between that point and the corona wire. Under the action of electric field force, a corona zone is formed inside the entire precipitation electrode tube. In the corona zone, high concentration negative ions (electrons) continuously move in a directional manner from the corona electrode to the precipitation electrode tube, forming a corona current. When smoke containing water mist and other pollutants enters the sedimentation electrode tube, due to the collision and diffusion of ions, the water mist and pollutants are charged, and then quickly reach the inner wall of the sedimentation electrode tube under the action of electric field force and release charges at the same time, forming a liquid film on the inner wall of the sedimentation electrode tube. The liquid film flows under gravity to the collection tank at the lower part of the electrostatic demister for centralized treatment, thus achieving the purpose of capturing fog droplets and other pollutants in the smoke. Suitable for smoke pollution scenarios such as circuit boards, dyeing and finishing, rubber products, electronic processing industries, recycling of waste plastics and rubber, enameled wires, molds, CNC, etc.

biological filter bed

Wet biofilter bed can be used for the treatment of odorous waste gas. It utilizes efficient microbial strains in high-efficiency biofilters to treat odorous waste gas containing hydrogen sulfide, ammonia, and other substances. The treatment process involves the biological oxidation and decomposition of pollutants in the exhaust gas through a specially cultivated microbial membrane on the biological packing in the biofilter. Suitable for industries such as wastewater treatment, food processing, feed processing, and garbage disposal.

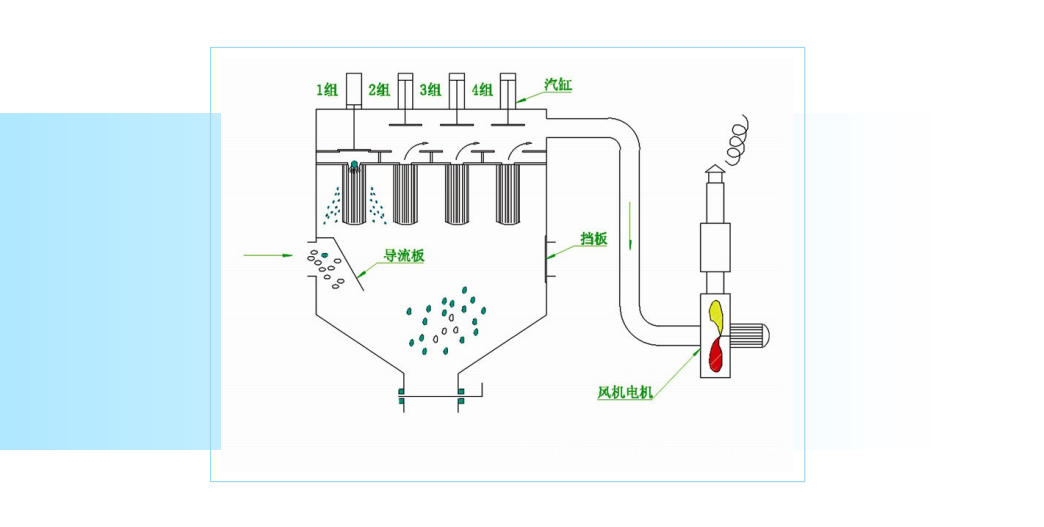

Pulse bag filter

Pulse bag filter is a mature dry dust removal equipment. When the dust containing gas enters the ash hopper through the guide plate at the inlet of the dust collector, due to the collision of the guide plate and the decrease in gas velocity, the coarse dust falls into the ash hopper, and the remaining fine dust particles enter the filter bag chamber with the gas. Due to the inertia, diffusion, and barrier of the filter fiber and fabric, the dust is trapped outside the filter bag, and the purified gas escapes from the bag and is discharged through the exhaust port. The dust accumulation on the filter bag is removed by spraying pulse air flow. The removed dust is discharged to the ash hopper, and then discharged to the ash conveying device through the double-layer ash discharge valve, and then discharged by the ash discharge device. Suitable for capturing small, dry dust.

cyclone dust collector

A cyclone dust collector is a dust and exhaust gas treatment equipment that uses dusty airflow to change direction and generate centrifugal force to separate and capture dust particles. The structure of a cyclone dust collector is simple, compact, occupies a small area, has low cost, and is easy to maintain. It is suitable for high concentration dust, but the disadvantage is that it is not efficient for fine dust.

Activated carbon adsorption concentration+catalytic combustion equipment (CO)

Activated carbon adsorption concentration+catalytic combustion equipment is mainly used for low concentration, high air volume organic waste gas treatment. It uses activated carbon to adsorb organic pollutants in the waste gas. After adsorption saturation, the adsorption is stopped, and the saturated activated carbon adsorption box is automatically controlled by the program to switch alternately with the activated carbon adsorption box that is ready for use after desorption. CO (catalytic combustion equipment) automatically heats up and sends hot air into the activated carbon adsorption box through a fan to desorb organic pollutants adsorbed in the carbon layer. The desorbed exhaust gas has been concentrated and enters the catalytic combustion device for catalytic combustion into carbon dioxide and water vapor, which are then discharged. This device is widely used in fields such as spraying, printing, coating, injection molding, coating production, ink printing and dyeing.

Zeolite impeller/drum is an organic waste gas (VOCs) adsorption and concentration device, mainly targeting high air volume and low concentration organic waste gas. After adsorption purification and desorption, it is converted into low air volume and high concentration organic waste gas, which is subjected to thermal oxidation treatment and effectively utilizes the heat released by the combustion of organic matter. This device is widely used in fields such as spraying, printing, coating, injection molding, coating production, ink printing and dyeing.

Zeolite wheel/drum

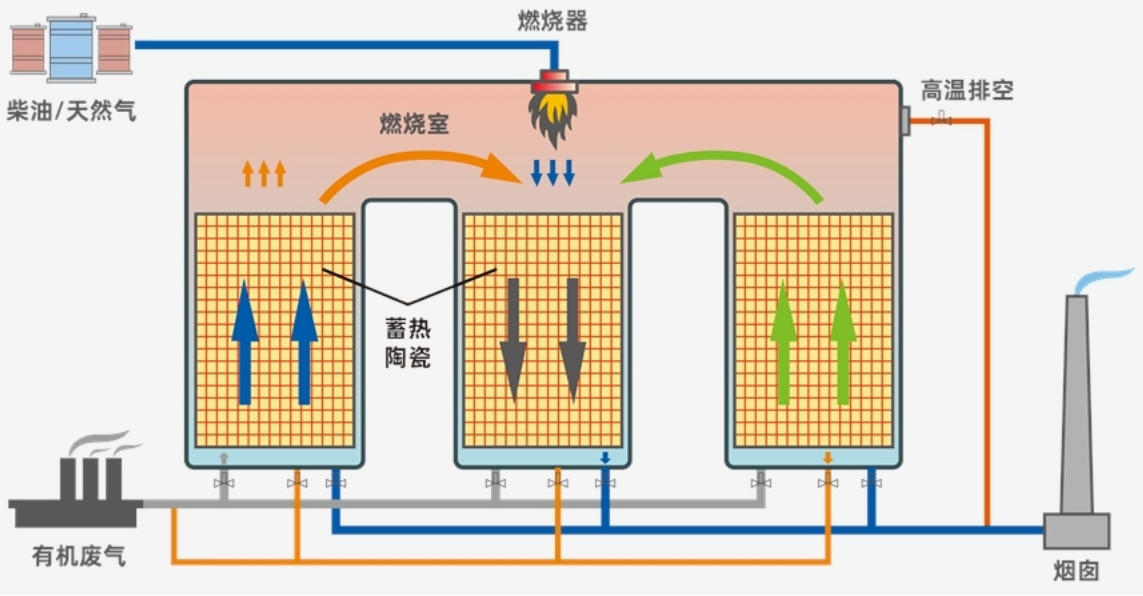

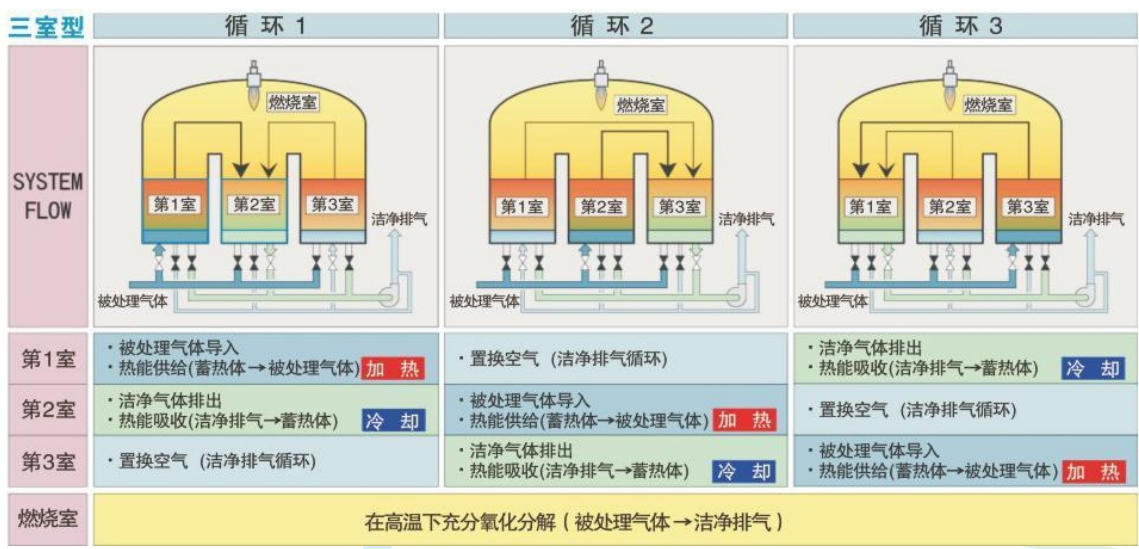

Thermal Storage Incinerator (RTO)

Regenerative incinerator is an efficient organic waste gas treatment equipment. Its principle is to oxidize organic pollutants in the waste gas into CO and H, 0 under high temperature conditions, thereby purifying the waste gas and recovering the heat released during the decomposition of the waste gas. The treatment efficiency of RTO reaches over 98%, and the heat recovery efficiency reaches over 95%. This device is widely used in industries such as spraying, printing, coating, chemical engineering, coating production, and pharmaceuticals.

process flow:

When the exhaust gas enters the ceramic packed bed, it is heated to above 800 ℃, undergoes oxidation reaction, generates carbon dioxide and water, and then enters the ceramic packed bed to generate heat. The heat is stored in the ceramic packed bed, and the low-temperature clean gas is discharged into the chimney by the fan. Subsequently, clean air is introduced into the ceramic packed bed to blow away the waste gas trapped in the previous cycle. Through the switching of multiple switching valves controlled by PLC, multiple ceramic packed beds are rotated for heat storage heat release cleaning process.

Equipment advantages:

1、The exhaust gas treatment facilities meet the required treatment capacity and operate stably, and all pollution indicators meet the relevant national and regional pollutant emission standards.

2、Low investment, operation, and maintenance costs can fully leverage the social, economic, and environmental benefits of facility purification.

3、Advanced and reasonable technology, fully considering operational safety factors, ensuring reliable operation.

4、The automation level of processing facilities is high, which facilitates the operation and management of equipment.

5、The equipment has a beautiful appearance, compact and reasonable layout, convenient management and maintenance, and does not affect the use and maintenance of the production system during use.

PCB dust collection and treatment system

Dust hazards not only endanger human health, but also cause significant environmental pollution. Industrial dust collection equipment has evolved from a single environmental protection device to an indispensable production equipment in industry, widely used in industries such as dry PCB circuit board, battery, electronics, and automotive manufacturing.

The PCB dust collection and treatment system consolidates multiple dust production points, or even the entire workshop or factory's dust production points, into one dust removal system for processing. Suitable for situations where there are many dust points, relatively concentrated, with large exhaust volumes at each point, and there is space to install large-scale dust removal facilities.