Process Introduction

process introduction

Gold, palladium precious metal recovery equipment

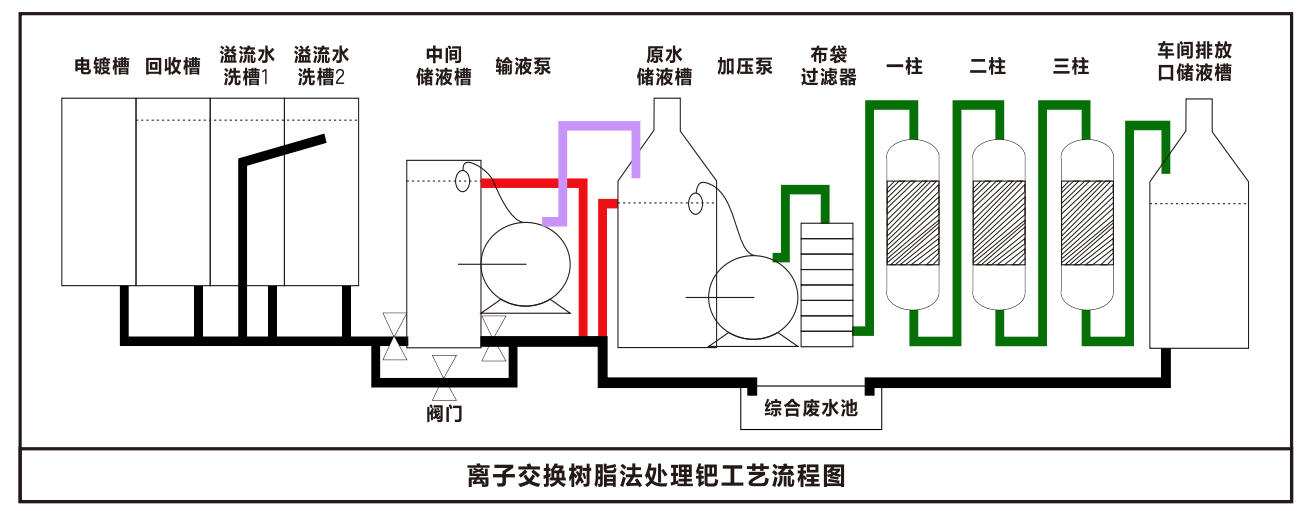

Palladium recovery and treatment system for palladium-containing waste liquid and rinsing wastewater

The system is a set of high-tech, clean production, environment-friendly palladium recovery system, according to the actual situation of users, in the palladium process will produce palladium containing waste water, rinsing wastewater, our company provides palladium treatment equipment, is specifically for the treatment of micro palladium ions in water, almost complete recovery of precious metal palladium. The system has the characteristics of simple maintenance, small floor space, no change of original production process, etc. The filler of the equipment is regularly recycled by our company for harmless treatment.

Description of treatment process flow:

Ion exchange resin adsorption is operated by ion exchange column series full saturation process. Single column specification is Φ 300 x 1500. When the palladium content of the resin in the exchange column reaches saturation, the resin is taken out to recover palladium. Add new resin and repeat the process. After treatment by the exchange column, the effluent is generally discharged.

Project advantages:

The palladium adsorption material of this project is resin. Resin is used to adsorb palladium on the production line. Resin regeneration equipment provided by our company is used to regenerate resin. Resin can be reused. After desorption, resin is transformed (regeneration process) and returned to production for use. The palladium adsorption effect is basically the same as that of the first resin adsorption. Compared with carbon adsorption palladium, it has the following advantages.

1. The adsorption material can be reused without the need to open the joint leather transportation, reducing the risk of transportation. After carbon adsorption, it can only be incinerated, which has a great impact on the environment. The recycling of the field is more in line with the current national poor cleaning production policy.

2. The recovery of Pd in incineration process is not guaranteed, and the recovery rate is lower than that of resin regeneration.

3.

Our company has service personnel in the field service maintenance, and

your company to participate in the project personnel to work together

on a regular basis and check, to ensure the adsorption effect of

equipment.

Gold recovery and treatment system for gold-containing waste liquid and rinsing waste water

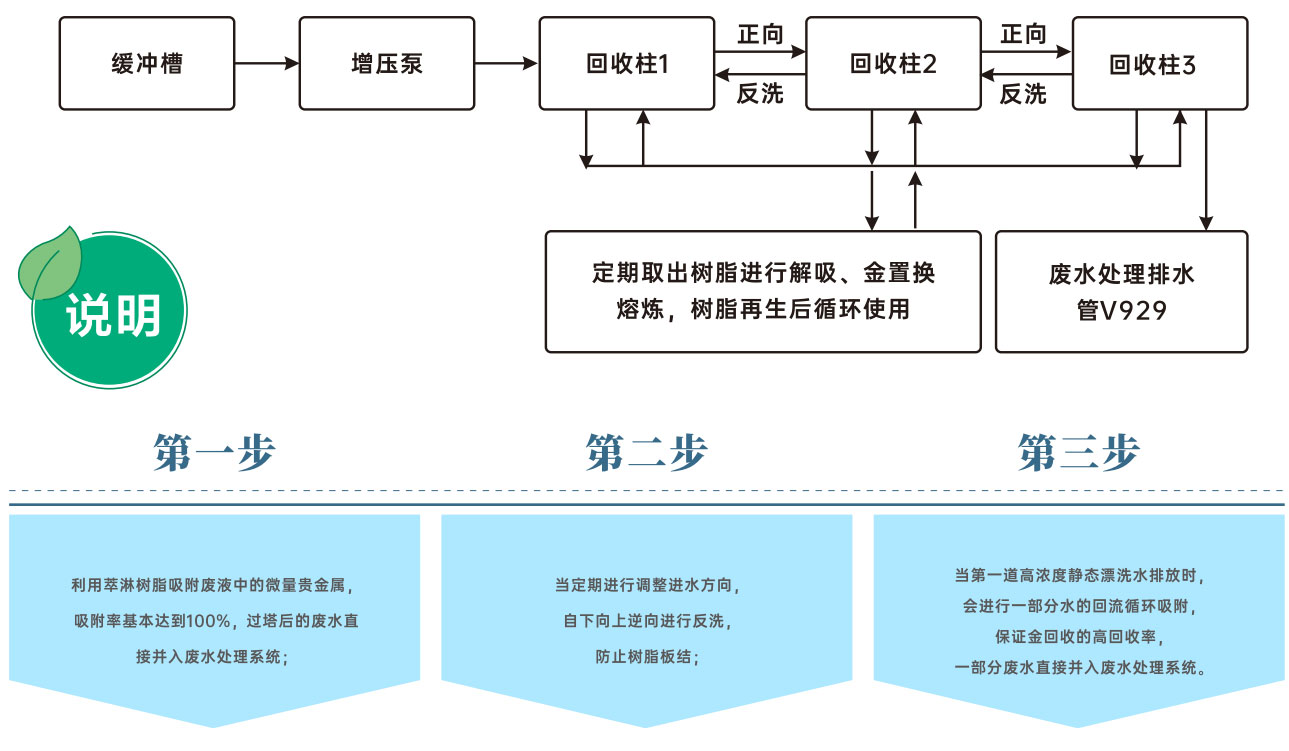

The system is a set of high-tech, clean production, environmental protection gold recovery system: according to the actual situation of users, in the gold-containing process will produce gold-containing waste water, rinsing wastewater, our company provides gold-containing treatment equipment, is specifically for the treatment of micro-gold ions in water, almost complete recovery of precious metal Au. The system has the characteristics of simple maintenance, small floor space, no change of original production process, etc. The filler of the equipment is regularly recycled by our company for harmless treatment.

Technical features:

After years of careful research and development, our company has obtained advanced new gold recovery technology. Through this technology, metal substances contained in wastewater are treated by exchanging opposite ions on the active gene of ion exchange resin with same-sex ions in solution. Noble metals are basically completely adsorbed on the resin in the resin tower. When adjusting the water inlet direction regularly, reverse washing is carried out from bottom to top to prevent resin hardening and remove bubbles and impurities around the resin. Keep the gap between the resins and ensure the recovery rate of gold recovery.

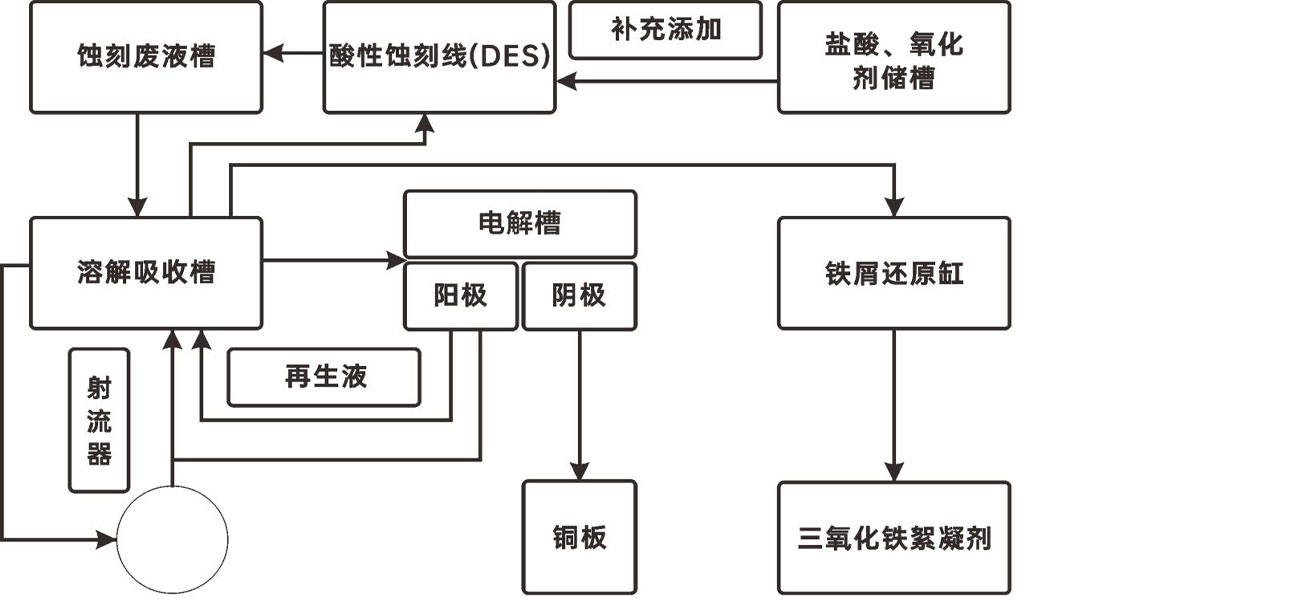

Acid etching solution regeneration and copper recovery equipment

Process Description:

The

system electrolyzes and recovers copper ions from etching solution by

diaphragm electrolysis process principle, and realizes regeneration and

recycling of acidic etching waste solution.

The electrolytic cell

adopts the "diaphragm electrolytic copper process", which is divided

into a cathode chamber and an anode chamber by a diaphragm. The cathode

chamber and the anode chamber are respectively provided with a cathode

plate and an anode plate, and are connected with a current control

device: each cell is connected with the electrolytic cell by a pipeline

and forms a closed circuit. When the waste liquid enters the

electrolytic cell, electrolytic reaction occurs under the action of the

polar plate. Precipitation and recovery of copper in cathode chamber:

chlorine generated in anode chamber is absorbed by etching solution

after etching, and univalent copper is converted into divalent copper.

Univalent copper is electrolytically oxidized into divalent copper, and

the bath solution is recycled after entering mixing tank.

After

passing through this system, copper ions are reduced, and the purpose of

etching solution regeneration and copper recovery is achieved. This

innovative technology is at an industry leading level.

Product Features:

1. This equipment process adopts the principle of jet absorption + alkali absorption (iron absorption) to treat acid mist. The floating water (molten iron) solution obtained by reaction can be used as ammonia nitrogen wastewater (flocculation wastewater) in wastewater treatment station, which can reduce wastewater treatment costs. The treated gas can be discharged after being purified by waste gas tower.

2. The liquid medicine is regenerated by electrolysis, which saves the cost of sub-liquid and reduces the production cost (depending on the customer's situation, there is a waste liquid amount of 0:15% increment).

3. recovering copper ions in waste etching solution to obtain high-purity electrolytic copper.

4. High degree of automation, simple system operation and maintenance, installation and debugging does not affect production. The whole system is equipped with a number of monitoring devices such as specific gravity detector, ORP monitor, PH meter, flow meter, etc., which control the operation data of the whole system in real time, which not only reduces the labor intensity of employees, but also ensures the normal operation of the system.

Alkaline etching solution regeneration and copper recovery equipment

Process Description:

The

system is a closed cycle process of etching

solution-extraction-electrowinning (ET-SX-EW) regeneration, which

fundamentally solves the problem of sulfate radical existing in the

original process.

(SO2-) and chloride ion (CL) entrainment problem, overcome the defects of the original process.

When the process is used to treat the invalid etching solution, it can be adjusted at will, and a certain amount of copper or all copper can be extracted from the extracted solution. The extracted copper can be produced by electrodeposition. Ammonium (NH.CL,(NH),HCO,) in the residual solution after extraction has no loss basically, and can be recycled back to the etching system after regeneration.

This process adopts foreign advanced extractant and extraction equipment, which can reduce the problem of extractant loss caused by entrained organic phase, maintain the level of less extractant consumption, and ensure the stable proportion of organic phase and aqueous phase. Therefore, the use of this process can reduce investment, maintain stable operation, and can obtain greater economic benefits for enterprises.

Product Features:

The regenerated etching solution can be recycled, saving the cost of purchasing etching solution. Because this system can recycle etching solution, it is no longer necessary to purchase etching solution after using this system, which can reduce the production cost of enterprises. Moreover, the copper content of the etching solution regenerated by the system is stable, so the quality of the plate will be better.

Copper ions in the etching solution are reduced to valuable high-purity metallic copper. This system can convert copper ions in waste etching solution into pure metallic copper (99.99%), and considerable cash profits can be obtained by selling metallic copper. And enterprises can use the cash income to add other advanced production equipment.

Tin stripping waste liquid regeneration and tin recovery equipment

Product Features:

After tin stripping process adopts online clean production, it can greatly reduce waste liquid emission, reduce a large number of tin stripping waste liquid transfer that needs to issue transfer orders, reduce transportation risks, and meet the spirit of energy saving, emission reduction and clean production advocated by the state.

Tin stripping solution recycling, reduce a large number of high COD, high nitro-nitrogen wastewater discharge, reduce treatment pressure.

Recycling reduces chemical consumption and saves PCB stripping costs.

Reduce the original several times a day row, change slot time, reduce the operation intensity of employees, indirectly improve the efficiency of PCB enterprises: can obtain a valuable by-product-tin mud. Its main functions and characteristics are as follows: it can use the cash of income to add other advanced production equipment.

Copper-containing waste liquid recovery and treatment system

In the system, waste liquid such as copper sulfate, microetching solution, browning solution and the like is pretreated by a pretreatment device, the concentration of hydrogen peroxide and organic matters is reduced, electrolysis is carried out by an electrolysis device, electrolysis is stopped when the concentration of copper ions is lower than about 2-5g/L, and low-copper-containing waste water is discharged to a waste water treatment station for treatment. Cu2 + is reduced to elemental copper under the reduction action of electrode cathode, so that the concentration of Cu2 + in waste liquid is reduced by more than 95%, and it is easy to discharge waste water treatment, reduce the pressure of environmental protection treatment of Cu2 +, and obtain a by-product with economic value-electrolytic plate-like copper in the process. The equipment has the advantages of small equipment occupation, small investment, simple and easy operation. the electric efficiency is more than 70 percent, and the cost is low.

COD and copper recovery equipment for browning waste liquid

Process Description:

Copper extraction and COD reduction process of browning waste liquid is to deposit copper ions in browning waste liquid on cathode plate in the form of high-purity elemental copper through electrolysis after browning waste liquid is treated by four modules of pretreatment, complex breaking, oxygen breaking, electrolysis and tail gas treatment, and at the same time, most of organic matters in raw liquid are broken down after the whole treatment process, and the COD value is greatly reduced, so that the solution after electrolytic copper removal is easily treated and discharged to the wastewater station.

Product Features:

Cathode copper obtained by electrolysis has high purity, which can reach more than 96%.

The waste gas tower is equipped with automatic addition control device to calibrate and overhaul the induction probe regularly to prevent the waste gas from not reaching the standard emission;

Storage containers are equipped with double high liquid level sensing alarm to prevent leakage of solution;

COD value of the stock solution can be reduced by more than 90%;

The equipment occupies a small area and the input cost is low.

Microetching waste liquid regeneration and copper recovery equipment

Process Description:

The microetching solution regeneration and copper extraction process is that after microetching waste liquid is processed by four modules of pretreatment oxygen breaking, electrolysis, regeneration solution adjustment and tail gas treatment, copper ions in microetching waste liquid are deposited on cathode plates in the form of high-purity elemental copper through electrolysis, and at the same time, the components of the electrowinning copper solution are adjusted to make each index meet the requirements required by production. At this time, it can be called regenerated subsolution, and it can be automatically added back to microetching production line for use through plate area control. Thereby realizing the circular utilization of resources.

Product Features:

Cathode copper obtained by electrolysis has high purity, which can reach more than 96%.

The waste gas tower is equipped with automatic addition control device to calibrate and overhaul the induction probe regularly to prevent the waste gas from not reaching the standard emission;

Storage containers are equipped with double high liquid level sensing alarm to prevent leakage of solution;

can realize the recovery and utilization of copper removing solution;

The equipment occupies a small area and the input cost is low.

Etching solution production Copper salt recycling products

Background analysis:

A

large amount of acid and alkali etching waste liquid is produced in the

PCB industry manufacturing process. Due to the high content of waste

liquid, it has good recycling value. At present, the general acid and

alkali etching waste liquid is outsourced to qualified units for

recycling. However, there is a potential risk of leakage in transit

during outsourcing.

In accordance with the national environmental

protection policy, large-scale waste-producing enterprises are allowed

to treat hazardous wastes in their plants under fully demonstrated

circumstances. Since Jingwang Electronics has a large-scale PCB

manufacturing plant in Longchuan Shenzhen (Bao 'an) Industrial Transfer

Park, the construction of waste liquid recycling facilities in the park

can not only avoid the risk of accidental leakage during outsourcing

disposal and transportation, but also realize waste utilization and

clean production, reduce hazardous waste generation, and bring good

social and economic benefits to enterprises.

Main treatment process and design scale:

15000 tons/year (1200 tons/month) etching waste liquid recycling line, copper-containing alkaline etching solution treatment 6000t/d, copper-containing acidic etching solution treatment 9000t/d.

540 tons/year (45 tons/month) tin stripping waste liquid recycling line.

Etching solution recycling treatment capacity 15540t/d(24 hours continuous operation, annual operation days for 300 days design).

The waste liquid of the project is mainly the acidic etching solution containing copper and alkaline etching solution containing copper produced in the etching process of Jingelectronic Technology (Longchuan) Co., Ltd. Tin coating, tin-lead alloy coating and tin stripping waste liquid produced by stripping tin welding points.

Main product description:

copper sulfate

Copper sulfate, alias blue alum or chalcopyrite.

Copper is an essential trace element for animals. It is involved in heme synthesis, erythrocyte maturation and osteogenesis. Pigmentation and keratinization of hair and fur act as components (or as cofactors) of several important enzymes in animals. High copper (250mg/kg) can improve the daily gain, feed intake and feed efficiency of weaned piglets. Therefore, high doses of copper sulfate are mostly added to pig feeds in China.

Industrial production of copper sulfate commonly used products are mainly agricultural copper sulfate, feed grade copper sulfate, copper sulfate plating grade. The copper sulfate produced in this project shall be implemented in accordance with the various indicators of copper sulfate specified in "GB437-2009 Copper Sulfate".

basic copper chloride

Basic copper chloride is also called copper oxychloride.

Green crystalline powder packed with fine sand, uniform particles, good fluidity, no moisture absorption, no agglomeration, stable in the air. It is beneficial to improve the mixing uniformity of copper added in feed, so as to better prevent high copper poisoning. Appearance for dark green and light green powder or particles, no visible foreign impurities. Widely used in feed industry, chemical industry, pharmaceutical industry, veterinary industry and pesticide industry.

Copper sulfate is easily soluble in water, easy to deliquesce, strong oxidation promotion effect, high dose in feed is easy to destroy the nutrition of D and other trace elements produced antagonistic effect, resulting in the increase of the amount of addition, increase feed costs. Basic copper chloride has attracted people's attention for its safety, high efficiency and non-moisture absorption. In 2003, the Ministry of Agriculture approved basic copper chloride as a national new feed additive, which has been promoted and applied nationwide: in the United States, since the early 1990s, it has been applied in livestock feed.

Intelligent integrated environmental protection solutions

The introduction of safety management means such as double-layer liquid level alarm protection, overflow collection system, SMS telephone alarm reminder and video monitoring, together with the automation and intelligent operation data collection of the processing system itself, ensure the efficient and safe operation of the system.